Contact Polyplas’ Anchor specialist, Sam Smith, today to discuss how Liebig Undercut Anchors could elevate your next project.

Sam Smith | Commercial Development Manager

+61481731625 | sam.smith@polyplas.com.au

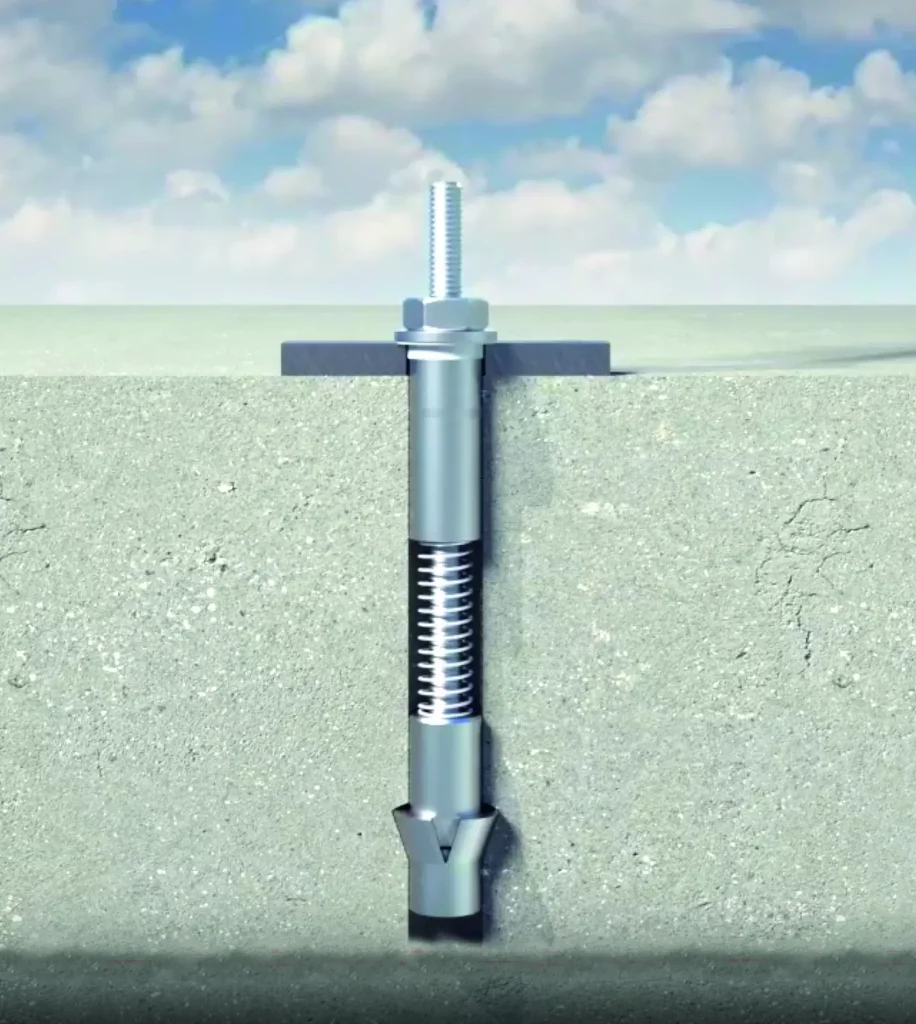

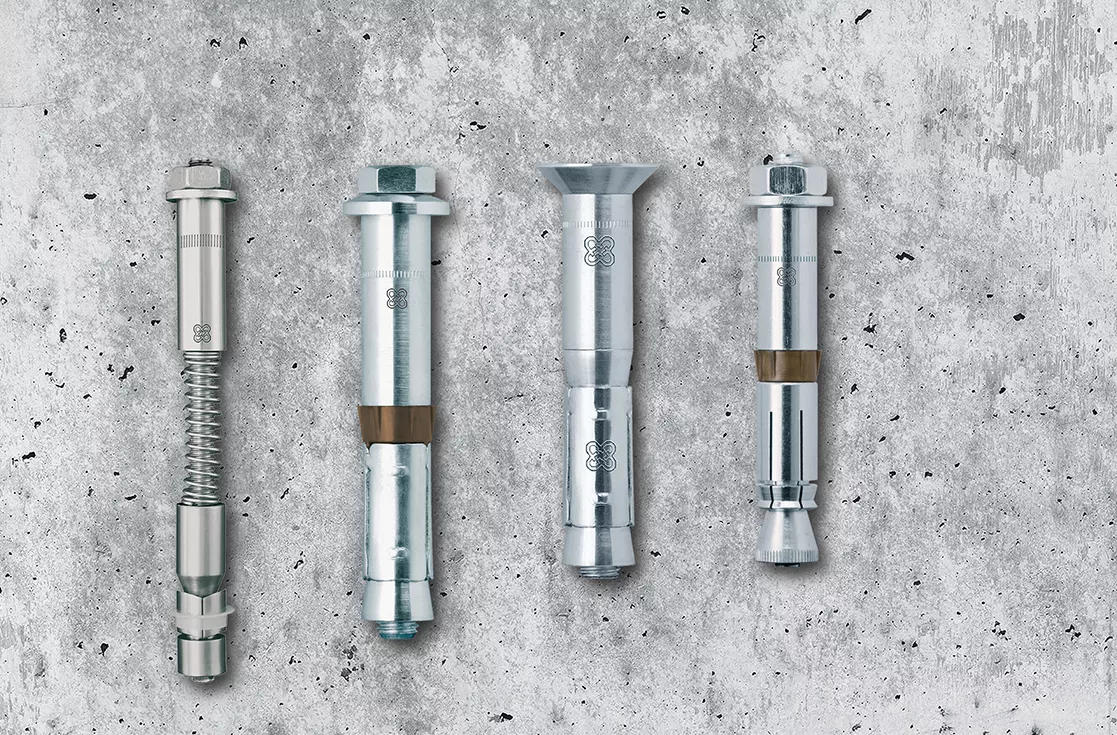

Undercut anchors are specially designed for high-performance applications in concrete, ensuring a secure and reliable connection. Unlike traditional expansion anchors, undercut anchors create a mechanical interlock within the concrete, delivering exceptional load-bearing capacity and long-term stability

Advantages of Undercut Anchors

Undercut anchors are ideal for structural steel connections, façade systems, heavy-duty machinery installations, and seismic applications. Their high performance makes them a dependable solution for demanding construction environments.

The Liebig Ultraplus uses a special undercutting tool to form a void at the bottom of the drilled hole. When inserted, its spring-loaded mechanism forces expansion keys into the void, creating a secure interlock. This ensures maximum load capacity, utilising the anchor’s steel strength rather than relying on concrete friction.

Key Considerations: Undercut Anchors

To ensure optimal performance and safety, several factors must be considered:

Watch the Undercut Anchor video playlist here to explore all product showcases of the Liebig concrete support anchor range

Contact Polyplas’ Anchor specialist, Sam Smith, today to discuss how Liebig Undercut Anchors could elevate your next project.

+61481731625 | sam.smith@polyplas.com.au